UV printer home appliance panel printing operation

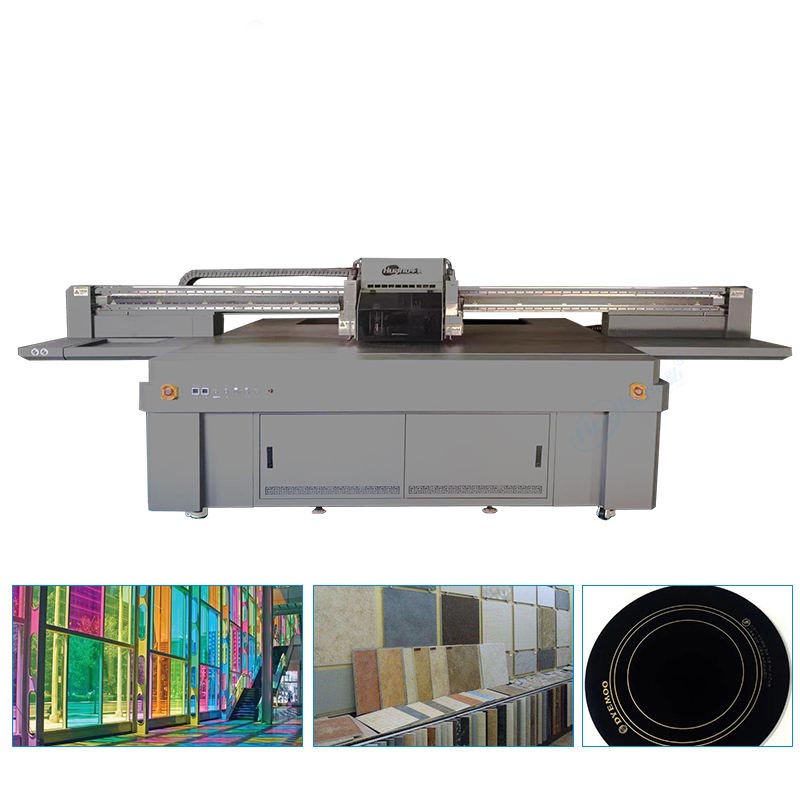

Home appliance panels are mostly made of PVC material, and using UV printers to print various logos, logos, and personalized patterns on the panels has become a common application. The editor has briefly organized the operation steps for UV printers to print home appliance panels for you. Due to the panel being made of sheet metal, using a UV flatbed printer is sufficient. Some household appliance panels have brackets, which can print unevenly on UV flatbed printers, making it easy to scratch the nozzle. In addition, the car and tabletop are too high, and UV light at the edges can easily reflect onto the nozzle, causing instant blockage. The following will provide a detailed description of the printing method for such panels.

UV printer home appliance panel printing operation

1 Front and back of the finished product.

2 Prepare the placement mold for the panel, which can ensure a smooth placement of the panel. Place light barriers around the perimeter, with a width similar to that of a small car.

3 Check again if the panel is raised, and then measure

4 You can lift the collision bar and gently push the car over the panel to check for any scratches.

5 Start printing. Home appliance panels with simple shapes or good flatness can be directly placed on UV flatbed printers for printing.

We welcome new and old customers to call us for consultation. Our company supports small batch customization and exterior design,

We have strong research and development capabilities and are a trusted manufacturer. Welcome to call or sales@molddl.com Consultation, 24-hour online business and technical consultation, professional after-sales service, and thoughtful repair application service!